Machine Embroidery Stabilizer Basics

Beautiful machine embroidery results begin with choosing the right stabilizer for your project. Stabilizer is the foundation for a successful embroidery project. It stabilizes the fabric and keeps it from moving, puckering, or stretching while embroidering. Stabilizer keeps the stitches looking good after embroidery by adding stability to the fabric.

Without a stabilizer (or too little stabilizer), embroidery designs will have puckers, holes in the fabric, and alignment problems, like gapping between the fills and the outlines of the designs.

What is a stabilizer made of?

Most stabilizers are non-woven material, made in a process where the fibers are smoothed into a single consistent layer. All OESD stabilizers are made with a non-directional process, which means they are equally strong in all directions. Because of this, it does not matter which direction you cut or hoop your stabilizer, as there is no grain to the material. For tearaway stabilizers, this non-directional feature also means that the stabilizer will tear evenly in all directions.

When selecting an embroidery stabilizer, it is essential to look for consistency in the fibers. If you hold the stabilizer up to the light and you can see obvious inconsistencies, those lighter areas will provide less support than the thicker areas, which can result in alignment issues with your design.

What makes OESD stabilizers different?

OESD stabilizers are developed by our team of embroidery experts with many years of experience in both commercial and home embroidery. Each stabilizer is thoroughly tested for quality and ease of use before it is given the OESD name. OESD stabilizers do not stretch in any direction, ensuring good quality embroidery, even on knits. You will notice the high quality and consistency of OESD stabilizers, as well as their versatility for a variety of projects. OESD stabilizers are designed to be the foundation on which you can build quality embroidery!

Why are there so many kinds of stabilizers?

Different stabilizers are made to work with various applications. Many factors go into selecting the correct stabilizer, such as:

- Fabric choice: the weight and type of fabric

- Design density: how many stitches the design has over a given area

- How the project will be embroidered: can the project be hooped

- The desired finished result: whether the back of the embroidery shows or the stabilizer shows through the fabric

What are the types of stabilizers?

Stabilizers are generally categorized first by how they are removed: CutAway, TearAway, or WashAway. In addition to these three major categories, some items fall into a specialty category, as they either stay in the project or are tools to help with the embroidery process. These major types are color-coded:

In addition to how they are removed, stabilizers are also categorized by other factors. The first is stabilizer weight, such as light, medium, or heavy-weight stabilizer. Stabilizers are also identified by their application, such as a pressure-sensitive or water-activated adhesive. Also, some types are available in multiple colors to match fabric or prevent shadowing.

How do I select the stabilizer weight?

There are some basic guidelines for selecting stabilizer weight. The heavier the fabric and/or the denser (more stitches) the design, the heavier the stabilizer that is needed. You may get better results using two layers of a lighter stabilizer than a single layer of a heavier stabilizer, especially when stitching a heavy design on a lighter-weight fabric.

How do I store the stabilizer?

Since most stabilizers look alike, store them in the original packaging or clearly marked bags. Fusible and WashAway stabilizers tend to stiffen with exposure to the air, so they should be stored in sealed bags. OESD stabilizer rolls are wrapped in cellophane with a paper label wrapped around the outside of the stabilizer. After removing the cellophane wrapping, roll up the label and insert it into the stabilizer roll.

How do I hoop the stabilizer?

Always hoop stabilizer with the fabric wherever possible. It is helpful to use temporary spray adhesive to adhere the stabilizer to the fabric to secure the pieces while hooping. Remember to make sure both the fabric and stabilizer are flat and smooth, but not stretched, in the hoop.

How do I select the stabilizer type?

Selecting a stabilizer type is in part based on personal preference, but each type has features that make it suited to particular kinds of projects.

CutAway Stabilizer

CutAway stabilizer can be used on any fabric but must be used on knits or stretchy fabrics. Because the fabric stretches, unless a CutAway stabilizer supports it, the embroidery will also stretch. CutAway will keep the stitches in place and prevent them from breaking or distorting after embroidery. Use CutAway stabilizer on jersey knit, t-shirts, sweatshirts, knit kids’ clothing, afghan fabric, denim or other twill weaves, and most wearables. CutAway holds up best on items that will be frequently washed and worn.

For beginning embroiderers, using a CutAway stabilizer will give the best results in terms of stitch quality. While it is primarily used for knit fabrics, it can be used on almost any type of fabric and provides the most support, giving the best quality stitch-out with clean alignment. CutAway stabilizers hold the most stitches of all types of stabilizers. For example, a medium-weight CutAway could support as many stitches as a heavy-weight TearAway. For designs with a high stitch count or very detailed outlines, CutAway may be the best choice.

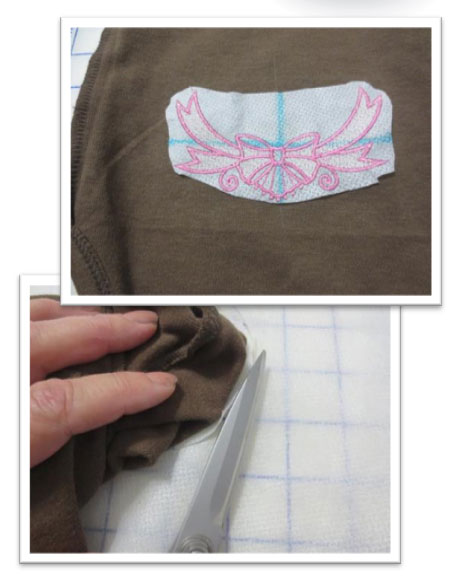

When removing CutAway, cut the stabilizer with scissors about ¼” from the edge of the embroidery, being careful not to cut the fabric while trimming the stabilizer. It is best not to cut the stabilizer closer than ¼”, as it is easy to nick the stitches, and trimming the stabilizer this close can cause a ridge around the embroidery.

CutAway stabilizer is available in several different types: Heavy, Medium, Polymesh, Fusible Polymesh, and StabilStick.

- Heavy Weight CutAway stabilizer comes in black or white and is used on knits and wovens, sweatshirt fleece, or stitch-intensive embroidery designs on any fabric.

- Medium Weight CutAway stabilizer comes in white only and is used on medium-weight stretchy fabrics, such as knits and lightweight denim. Use for large or stitch-intensive designs. Medium weight does soften after washing.

- PolyMesh CutAway is available in white and black. Use this for light-colored or thinner fabrics to prevent that shadow effect behind the fabric. It is extra soft and doesn’t irritate the skin, so it is perfect for baby projects. PolyMesh CutAway is soft but very strong and will keep your embroidery stitches looking good.

- Fusible PolyMesh CutAway comes in white only. It is fused to the wrong side of the project. It is not permanent, so the excess can be cut away. It is the choice for knits or lightweight wovens to maintain softness. Perfect for sweater knits.

- StabilStick CutAway is a high-quality, medium-weight stabilizer with a light adhesive coating. Use it on knits or stretchy fabrics, such as jeans, and hard-to-hoop items such as t-shirts, sweaters & slippery fabrics. It is ideal for projects that require multiple hoopings.

TearAway Stabilizer

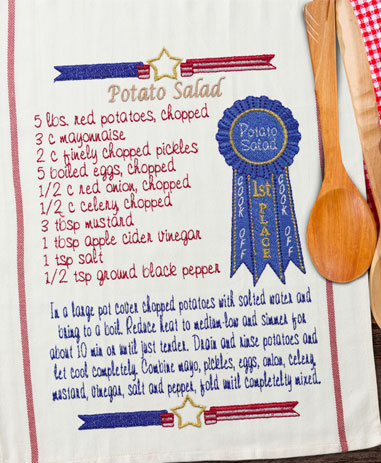

TearAway stabilizers are used in projects where most of the stabilizer needs to be removed, such as towels and linens. TearAway stabilizer can support more stitches than WashAway, but not as many as a CutAway.

TearAway stabilizer is often preferred because it is easy to remove and gives a cleaner look to the back of the embroidery. TearAway stabilizers are ideal for woven fabrics without stretch, such as chambray, poplin, quilt cotton, linen, and most satins. Also, use TearAway for sturdy ready-to-wear items like bags and hats.

TearAway is a common choice for appliqué designs because of its clean finish. The appliqué fabric in an appliqué design provides some stability to the project, so a lighter stabilizer can often be used.

TearAway stabilizers can also be used in other types of applications, such as decorative stitching on a sewing machine, or for stabilizing buttonholes.

OESD’s TearAway stabilizers have no directional tear; they will tear easily in either direction, and there is no need to crisscross layers.

When removing TearAway, support the stitches with one hand as you tear away the stabilizer with the other. Only remove one layer at a time. Remove the TearAway stabilizer from the outside of the design, but you can leave it in the open areas on the inside of a design.

TearAway Stabilizer is available in several different types: Heavy, Medium, Light, Ultra Clean and Tear, HydroStick, StabilStick, and Fusible.

- Heavy Weight TearAway comes in white only and easily supports stitch-intensive designs, as it has a stiff, crisp texture giving extra support. It is ideal for stitching designs with a large open area in the center of the design.

- Medium Weight TearAway comes in black and white color options. Best for designs with medium to high stitch counts. It is easily removed.

- Light Weight TearAway is available in white only and is used on lightweight fabrics to stabilize low stitch count designs. It is very easy to remove and is ideal for printing on for paper piecing quilt blocks.

- Ultra Clean and Tear is available in white only and is a high-quality, medium-weight TearAway. It provides excellent stabilization for medium to high stitch count designs, and easily and cleanly tears away from the stitches. Use on woven fabrics, including towels, when no permanent backing is desired.

- Ultra Clean and Tear Fusible is an iron-on, medium-weight TearAway stabilizer that provides excellent stabilization for medium to high-stitch count embroidery designs. Use on woven fabrics, including towels, when no permanent backing is desired.

- Ultra Clean and Tear Plus is a medium-weight TearAway, WashAway stabilizer with a water-soluble adhesive coating. Use on hard-to-hoop items such as collars, napkin corners, and towels. Ideal for tightly woven and slippery fabrics that do not stretch. Easily removed without distorting even the most delicate stitches.

- HydroStick is a medium-weight TearAway with a starch-based, water-activated adhesive coating. It works well for hard-to-hoop, firmly woven items such as napkins, ball caps, and collar points or bulky items such as heavy seam allowances, ensuring the item stays securely in place.

- StabilStick TearAway is a high-quality medium-weight with a light adhesive coating. Use it on hard-to-hoop items such as collars and napkin corners, and tightly woven and slippery fabrics with no stretch. It is ideal for projects that require multiple hoopings.

WashAway Stabilizer

WashAway stabilizers are made from a chemical starch that dissolves completely in water. When rinsed thoroughly, the stabilizer is completely removed from the fabric.

If a fabric is sturdy and the design is light enough, a WashAway can be used as the primary stabilizer. For sheer fabrics, such as organza, tulle, or batiste, WashAway stabilizer is the best choice, as even a TearAway stabilizer will show on these projects.

WashAway toppings create a smooth surface for embroidery with fabrics containing a pile or nap, such as towels. By laying a piece of WashAway stabilizer over the top of the fabric to be embroidered, the stitches form over the top of the fabric, looking smooth and even, without sinking into the fabric. WashAway is also used on in the hoop projects like freestanding lace or appliqué.

WashAway is the best choice for freestanding lace designs (unless otherwise noted). OESD recommends using one layer of AquaMesh and one layer of BadgeMaster to provide the perfect amount of stability for freestanding lace.

WashAway is removed by rinsing it under warm running water. Rinse the project completely before allowing it to dry, as the starch in the stabilizer can stiffen the fabric if it is not rinsed out.

WashAway Stabilizer is available in AquaMesh, AquaMesh Plus, StitcH2O, and BadgeMaster.

- AquaMesh WashAway is an opaque mesh water-soluble stabilizer, perfect for freestanding lace and sheer or lightweight fabrics such as batiste when all traces of stabilizer must be removed. It resists drying out or absorbing moisture and is easily removed with lukewarm water.

- AquaMesh Plus is an opaque mesh water-soluble stabilizer with a water-soluble adhesive coating. Use when embroidering hard-to-hoop items using low stitch count designs, when all traces of stabilizer must be removed. Ideal for use on sheer, fine, or lightweight fabrics, such as chiffon and organza. Rinses out easily with lukewarm water.

- StitcH2O is a water-soluble topping that does not stick to the embroidery foot. It has a textured finish for ease of handling. Excess stabilizer tears away easily – remove any remnants by dabbing them with water. Use on top of an item to be embroidered to keep stitches from sinking into the nap of the fabric.

- BadgeMaster is a heavy-weight water-soluble stabilizer that is perfect for freestanding lace or freestanding applique projects. Great for embroidery on sheer, lightweight, and fine fabrics. Use it when all traces of the stabilizer must be removed from the fabric. It rinses easily with lukewarm water.

Specialty Stabilizer

Specialty stabilizers have unique applications for specific types of embroidery projects. Some examples are using Fiber Form for creating sturdy standalone items, Fuse and Fix for easier applique stitching, and fusible products like Fuse and Seal or SoftWeb.

Specialty stabilizers include Applique Fuse and Fix, Fuse and Fleece, Fiber Form, Gentle Touch Backing, Fuse and Seal, Fusible Woven, SoftWeb, StabilStick, Top Cover, and Heat2Go.

- Applique Fuse and Fix is a specialty stabilizer used with designs containing applique pieces. One side is sticky, and the other is fusible, making applique a breeze. Does not gum up the needle and does not leave the applique feeling overly stiff.

- Fuse and Fleece is a lightweight fusible fleece that creates loft in embroidered items. Add texture to tote bags, quilt blocks, trapunto, and more. For use on woven fabrics.

- Fiber Form is a specialty stabilizer perfect for projects that require a firm base (boxes, hat rims, in the hoop, etc.). It holds its shape and is easy to manipulate. Easily trim away with scissors and machine washable or dry cleanable.

- Gentle Touch Backing is used as backing on embroidery that may be abrasive to sensitive skin and for covering uncomfortable seams.

- Fuse and Seal is a clear iron-on film for applying embroidery to most fabric without sewing. Great for applying pre-stitched designs to shirts or towels. The heat-activated bond withstands repeated washings.

- Fusible Woven is a lightweight woven fabric with all-over fusible and is available in white and black. It adds body to light to medium-weight fabrics and helps to prevent puckering. Can be used in combination with TearAway or CutAway stabilizers and is ideal for large embroidery designs or multi-hooped projects.

- SoftWeb is a paper-backed fusible web that keeps projects soft and flexible. It holds the applique securely without adding bulk. Easily and or machine finish, and it’s soft enough to quilt through. Fuses evenly without bubbling.

- StabilStick Template Sheets are a convenient method to line up continuous designs for quilting and borders. Print directly on them from your laser or inkjet printer. Their translucent design aids in previewing design placement. Reusable and repositionable.

- Top Cover is a permanent topping that prevents show-through on contrasting embroidery. It is great for fleece and textured fabrics.

- Heat2Go is a medium-weight clear film that can be used as a topper or stabilizer for specialty applications. It is easily removed without distorting even delicate stitches. The perfect topping for moisture-sensitive fabrics. A permanent solution to hold lofty fabric fibers in place under embroidery, such as towels, corduroy, velvet, wool, and fleece. For use with all fabrics that can tolerate ironing temperatures between 260°-300°F (120°-140°C) or cotton setting on most irons.

Stabilizer Reference Guide

OESD offers this stabilizer reference guide to help you identify which OESD stabilizer will produce the best results for your project given the density of your design and the material used.

Experience the OESD difference for yourself. Shop our full line of expert stabilizers or purchase a sampler guide for a close-up look and feel of our premium stabilizers. If you have any questions about stabilizer use, please contact our support staff at support@oesd.com.